The Duravant family of operating companies serve the food processing, packaging and material handling segments.

What is Case Packaging and Why is it Important for Businesses?

Case packaging plays a crucial role in the business world. It involves the design and production of containers for products during shipping and storage. According to a recent report by Freedonia Group, the global market for packaging is expected to reach $1 trillion by 2025. This emphasizes the significance of case packaging in ensuring product safety and effectiveness.

The importance of case packaging extends beyond mere aesthetics. It affects shipping efficiency and cost-effectiveness. In logistics, efficient packaging can reduce transportation costs by up to 30%. Additionally, quality packaging minimizes product damage. This could save businesses significant amounts in potential losses. However, not all companies prioritize this aspect, leading to missed opportunities.

Many businesses still overlook how case packaging impacts consumer perception. A study from Smithers Pira highlights that 72% of consumers feel that packaging influences their purchasing decisions. Despite these insights, many firms struggle to align their case packaging with brand values. There is a need for reflection on how packaging choices can affect brand image and consumer trust.

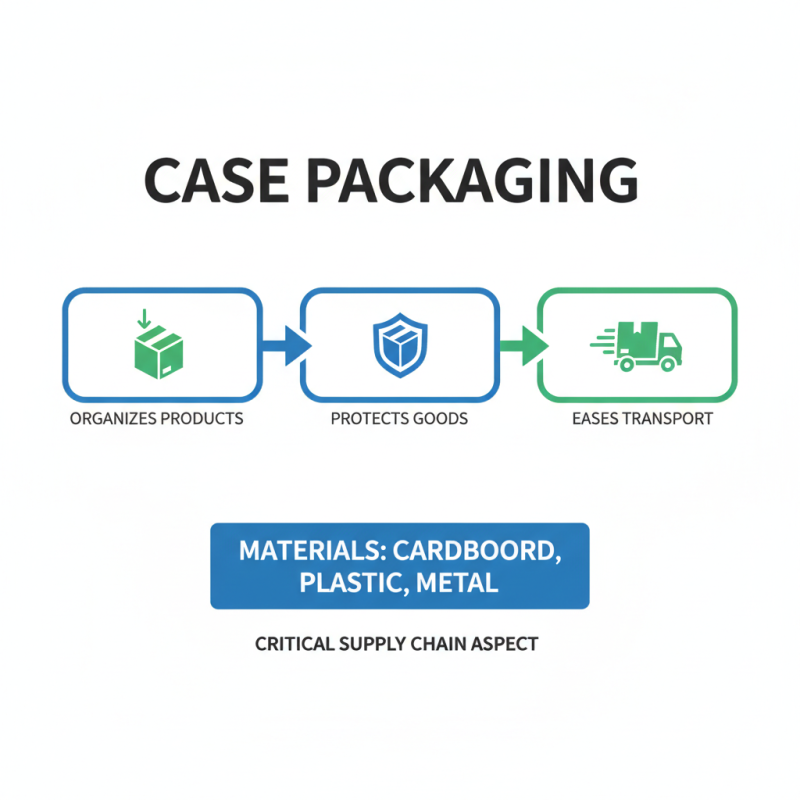

What is Case Packaging?

Case packaging refers to the process of packing products into cases for storage and shipping. It is a critical aspect of the supply chain. The case ensures that products are organized, protected, and easier to transport. This process often involves different materials, such as cardboard, plastic, or metal, depending on the product's needs.

Effective case packaging can significantly reduce damage during transit. Thoughtful design helps in stacking and storing items efficiently. However, not all packaging achieves this. Some businesses overlook the importance of choosing durable materials. This can lead to unnecessary losses and customer dissatisfaction.

Consider also the environmental impact. Many companies still use non-recyclable materials. This practice goes against the growing demand for sustainability. Finding a balance between protection and eco-friendliness can be challenging. Packaging should not just serve a practical purpose; it should also align with a business's values. In the end, case packaging is more than a necessity; it reflects a brand's commitment to quality and responsibility.

The Components of Case Packaging

Case packaging encompasses various components essential for product presentation and safety. It includes the outer carton and inner packaging, which protect items during storage and transport. Good packaging is durable yet flexible. For example, cardboard is commonly used as it absorbs shocks but can be recycled.

The size and design also play critical roles. Packaging must fit the product snugly. Too much space can lead to damage, while a tight fit can make unpacking difficult. Businesses often overlook the importance of aesthetics in packaging. Attractive designs can grab customer attention, but they must also be functional.

It’s crucial to consider environmental impact too. Some materials may not be sustainable, which can hurt a brand's image. Balancing protection, cost, and eco-friendliness is a challenge.

Perhaps we should question if we are doing enough to innovate packaging solutions that resonate with consumers and the planet.

The Benefits of Effective Case Packaging

Effective case packaging plays a vital role in business success. It serves not only to protect products but also to improve aesthetics. A well-designed package can attract attention on crowded shelves. However, finding the right balance between form and function is challenging. Many businesses overlook the impact of packaging design on consumer perceptions.

Investing in quality case packaging can lead to significant benefits. Enhanced protection reduces damage during shipping. This minimizes costs associated with returns and replacements. Moreover, effective packaging can improve brand recognition. Unique designs can create a lasting impression. However, some companies still use generic packaging. This can dilute their brand identity and miss opportunities to connect with consumers.

Sustainability is a growing concern in case packaging. Eco-friendly materials resonate with consumers today. However, transitioning to these options can be complicated and expensive. Businesses must weigh the environmental benefits against financial implications. The challenge lies in creating packaging that is both sustainable and appealing. Striking this balance is crucial for remaining competitive in an evolving market.

How Case Packaging Influences Supply Chain Efficiency

Case packaging plays a crucial role in supply chain efficiency. According to a report by the Association for Packaging and Processing Technologies, well-designed case packaging can reduce shipping damages by up to 25%. This reduction translates directly into cost savings for businesses, improving their bottom line. However, many businesses overlook the importance of selecting the right materials and designs, leading to increased waste and inefficiency.

In the logistics sector, packaging affects handling times. A study by the International Journal of Logistics Management found that optimized case packaging can improve loading and unloading by 30%. Yet, many companies still use packaging that is either too bulky or inadequately designed. This can result in wasted space, higher transportation costs, and delayed deliveries. Finding the balance between protection and efficiency is key but often neglected.

Additionally, consider the environmental impact. Sustainable packaging solutions can enhance brand reputation and meet consumer demand. A Consumer Goods Forum report indicates that 75% of shoppers are willing to pay a premium for sustainable packaging. Yet, some businesses hesitate to invest in these solutions, fearing initial costs. The challenge remains to innovate while ensuring efficiency across the supply chain.

Impact of Case Packaging on Supply Chain Efficiency

This chart illustrates the impact of various dimensions of case packaging on supply chain efficiency. A higher score indicates a greater importance for effective case packaging practices in reducing costs, minimizing damage, and enhancing customer satisfaction.

Case Packaging Trends and Innovations in Business

Case packaging is evolving rapidly as businesses adapt to new consumer demands. Trends show an increasing focus on sustainability. According to a recent report by Smithers Pira, the global market for sustainable packaging is projected to reach $400 billion by 2027. This shift is not just about materials but also about design. Many companies are now prioritizing smaller, efficient packaging that reduces waste. This trend reflects a growing consumer expectation for eco-friendly options.

Innovative packaging solutions are crucial for brand differentiation. The rise of e-commerce has led to a demand for packaging that protects products during shipping. Businesses are exploring materials like biodegradable plastics and reusable packaging. A report from Freedonia Group highlights that demand for eco-friendly packaging will grow at an annual rate of 4.2% through 2025. However, companies face challenges in balancing cost and sustainability.

The aesthetic appeal of packaging remains a priority too. Eye-catching designs can influence purchasing decisions significantly. Research indicates that 72% of consumers say packaging design influences their shopping choices. However, businesses must reflect on whether flashy packaging detracts from practicality. As trends shift, companies must find the sweet spot between innovation, sustainability, and functionality.

What is Case Packaging and Why is it Important for Businesses?

| Dimension | Description | Current Trends |

|---|---|---|

| Material Type | Types of materials used for packaging, including cardboard, plastic, and metal. | Increasing use of sustainable materials and biodegradable options. |

| Design Efficiency | Efficiency in design to maximize space and reduce waste. | Minimalistic designs to save space and reduce material usage. |

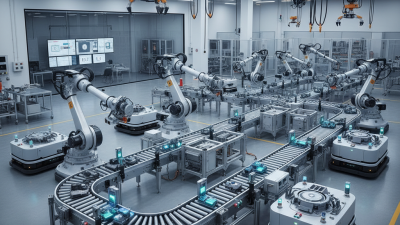

| Automation | Use of automated systems for packaging processes. | Integration of robotics and AI for improved efficiency and precision. |

| Consumer Preferences | Shifts in what consumers look for in packaging, including ease of use and recyclability. | Increase in demand for recyclable and reusable packaging options. |

| Supply Chain Impact | Influence of packaging decisions on the overall supply chain and logistics. | Focus on reducing transportation costs through optimized packaging. |

Related Posts

-

How to Choose the Right Case Packaging for Your Products: A Complete Guide

-

2025 Top 5 Innovations in Case Packaging You Can't Afford to Miss

-

How to Choose the Right Automated Packaging Equipment for Your Business?

-

2025 Top Trends in Packaging Automation Equipment: Efficiency & Innovation Insights

-

What is Packaging Automation and How Will It Evolve by 2026?

-

How to Implement Machinery Automation for Increased Efficiency and Productivity