The Duravant family of operating companies serve the food processing, packaging and material handling segments.

Why Is Packing Equipment Essential for Efficient Supply Chain Management?

In the fast-paced world of supply chain management, packing equipment plays a crucial role. According to John Smith, a leading expert in the packing equipment industry, “The right packing equipment can streamline operations and reduce costs.” His insight highlights the importance of selecting appropriate tools for different packaging needs.

Effective packing equipment ensures that products are secured during transit. This minimization of damage can save companies significant costs. However, not all businesses invest necessary resources into quality equipment. Often, companies focus on other areas and neglect their packing processes. This oversight can lead to inefficiencies and delays in the supply chain.

Inadequate packing equipment can result in a ripple effect throughout the logistics network. Items may arrive damaged, causing customer dissatisfaction. Companies may face returns and replacements, compounding costs. Reflecting on packing practices can lead to vital improvements in efficiency and service delivery. Engaging experts and constantly re-evaluating packing equipment can drive success in supply chains.

The Role of Packing Equipment in Supply Chain Efficiency

Packing equipment plays a crucial role in supply chain efficiency. Studies show that efficient packing can reduce shipping costs by up to 30%. Packing machines, such as sealers and fillers, streamline the packing process. This speeds up product delivery to customers. When packing is done manually, errors rise. Mistakes lead to returns and increased costs.

Implementing automated packing solutions can decrease labor costs by around 20%. However, not every company utilizes these systems. Some still rely on outdated methods. This can cause delays and wasted resources. In contrast, modern packing equipment minimizes space and maximizes protection during transport.

Data from the Warehousing Education and Research Council indicates that efficient packing reduces product damage by about 15%. Despite these benefits, many businesses overlook the importance of upgrading their packing processes. A lack of investment in packing technology can lead to inefficiencies. It’s a missed opportunity for growth in today’s competitive market.

Types of Packing Equipment Used in Supply Chain Management

Packing equipment plays a crucial role in supply chain management. Various types of packing equipment are vital for maintaining efficiency. Automated packing machines, for instance, can speed up the packing process significantly. Reports suggest that automating packing can increase productivity by up to 30%. This boost allows companies to handle more orders without increasing labor costs.

In addition to automated machines, manual packing stations are still widely used. They provide flexibility for unique items that require special handling. However, they can introduce variability in quality. Studies show that inconsistencies in packing can lead to customer dissatisfaction, impacting brand loyalty. Choosing the right packing solution is often a challenge that businesses need to address.

Void-fill packaging is another important type of packing equipment. It helps protect products during transit. This option can reduce shipping damages by as much as 19%. However, companies must be wary of over-packaging, which can be wasteful and costly. Achieving the right balance with packing materials remains a persistent issue in supply chain operations. This complexity underscores the need for companies to continually assess their packing strategies to optimize efficiency.

Why Is Packing Equipment Essential for Efficient Supply Chain Management? - Types of Packing Equipment Used in Supply Chain Management

| Packing Equipment Type | Primary Function | Benefits | Common Industries |

|---|---|---|---|

| Automatic Stretch Wrap Machines | Wrap products in stretch film for stability | Improves load integrity and reduces wastage | Logistics, Agriculture |

| Labeling Machines | Apply labels to packaging for identification | Enhances branding and compliant labeling | Food & Beverage, Pharmaceuticals |

| Carton Sealing Machines | Seal boxes with tape for secure shipping | Speeds up packaging process and reduces leaks | E-commerce, Retail |

| Filling Machines | Fill containers with liquids, powders, or granules | Ensures accurate filling and minimizes waste | Cosmetics, Chemicals |

| Shrink Wrapping Machines | Securely shrink wrap products with heat | Protects against tampering and environmental factors | Electronics, Retail |

Benefits of Effective Packing Equipment for Cost Reduction

Effective packing equipment plays a vital role in supply chain management. It helps reduce costs significantly while improving efficiency. Quality packing materials minimize product damage and waste. Properly packed items take up less space in transportation, which can lower shipping fees. These factors contribute directly to a company’s bottom line.

Tips: Always assess your packing needs. Consider the size and fragility of your products. Investing in suitable packing equipment now can save you money later. Shipping fees can add up. Ensure your packing process is streamlined to avoid delays.

However, not every packing solution works for every business. Some companies use too much packing material and waste resources. Others might choose cheaper options that compromise safety. Reflecting on your packing strategies can lead to better outcomes. Adjustments may be necessary to find the right balance for cost and efficiency.

Importance of Packing Equipment in Supply Chain Management

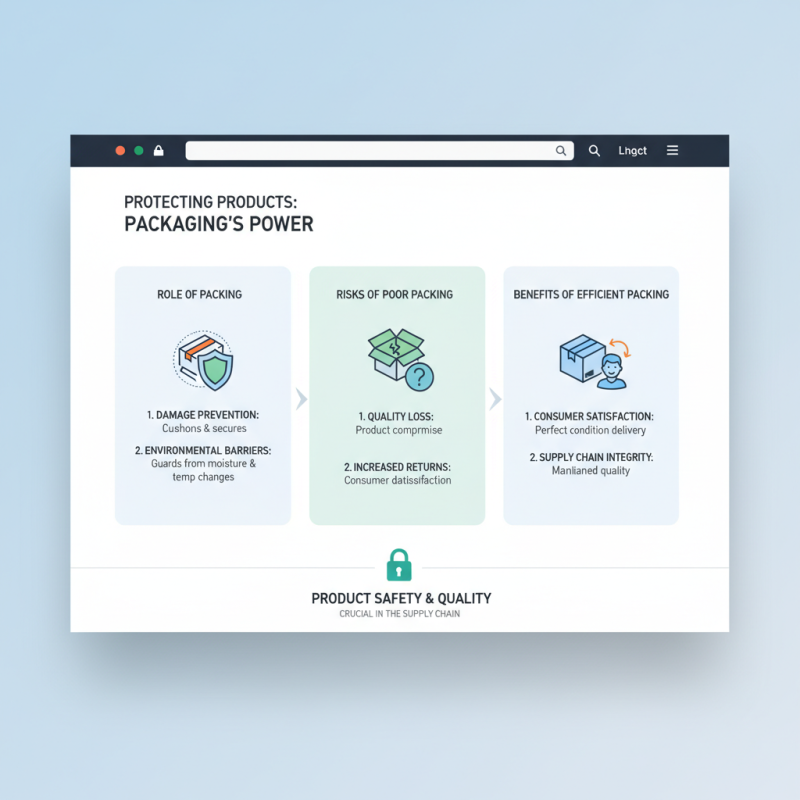

Impact of Packing Equipment on Product Safety and Quality

Packing equipment plays a crucial role in maintaining product safety and quality during the supply chain process. Proper packing protects products from damage. It keeps them safe from environmental factors like moisture and temperature changes. If packing materials are inadequate, products can be compromised. This can lead to loss of quality and increased returns. Efficient packing ensures that items reach consumers in perfect condition.

Furthermore, the choice of packing equipment affects how products are handled throughout the supply chain. If the packing is too tight, it could lead to breakage. Conversely, overly loose packing may allow items to shift during transport. Both scenarios can impact customer satisfaction. It’s essential to find a balance in packing methods to minimize risks. Many businesses overlook the importance of regular inspections for packing materials. This is critical for anticipating potential issues. Continuous improvement in packing methods can enhance overall product quality.

Integration of Packing Equipment with Supply Chain Technology

The integration of packing equipment with supply chain technology is crucial. Packaged goods need precision. Poor packing can lead to damages. According to a recent report by the Packaging Association, around 30% of goods are damaged during transit. This often results in significant financial losses. Proper packing equipment minimizes these risks.

Automatic packing machinery simplifies operations. Efficiency increases when machines handle repetitive tasks. A report from the Supply Chain Management Review highlighted that automation can cut labor costs by up to 20%. Yet, not all companies adopt this technology. Some still rely on manual packing. This approach can slow down the process. It also introduces human error, which can be costly.

Data shows that companies using advanced packing equipment report improved customer satisfaction. Quick and reliable deliveries enhance overall experiences. However, there is a challenge. Upgrading technology requires investment. Not every business can afford this. The key is finding a balance between cost and efficiency. Companies must reflect on their specific needs before making choices. This ensures their packing operations are not just efficient but also economically viable.

Related Posts

-

2025 Top 10 Packer Machines Revolutionizing Packaging Efficiency with 20 Percent Faster Processing

-

2025 How to Choose the Best Packer Machine for Your Business Needs

-

What is Packing Equipment and How to Choose the Right One for Your Needs

-

2025 Top 5 Food Bagging Machines You Need to Know About

-

Top 10 Innovative Industrial Packaging Solutions You Need to Know About

-

Top 10 Industrial Packaging Equipment You Must Consider for Your Business